概述:

1.扩展板基于STM32F4控制器,DRV8302 MOSFET 驱动器,IRFS7530 MOEFET.

2. 开源电调VESC,引出UART的TX/RX,适配Vision Board的UART2(RPI TXD2/RPI RXD2)发送/接收指令,完成速度和位置控制。

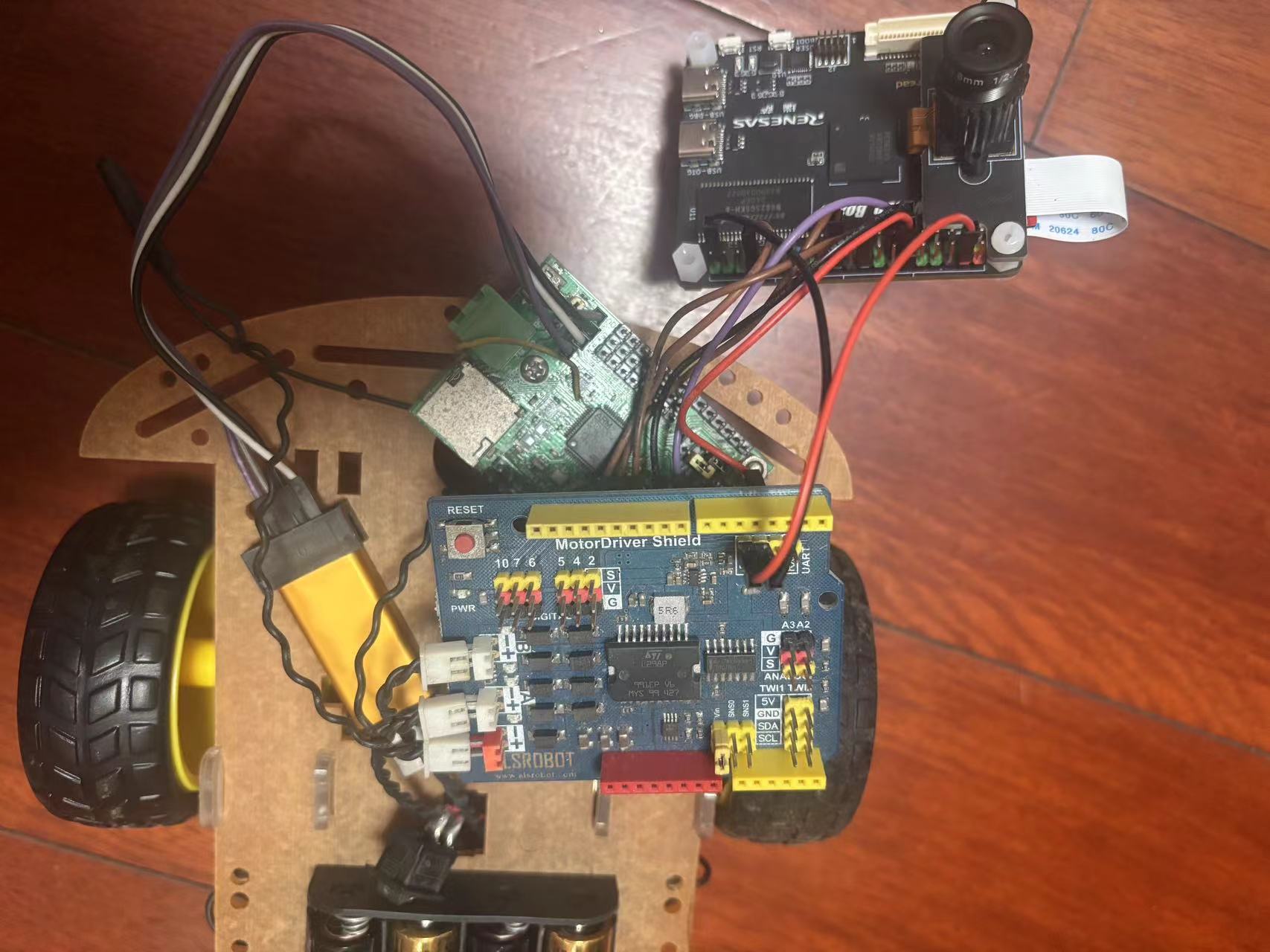

3.Vision board 接收路径线条数据,检测路线的中心位置偏差,计算转向和前进/后退指令。 电驱的模块专门用于电机执行和驱动的功能, 这样VisionBoard开发板让其专注于机器视觉处理如颜色跟踪等任务

硬件:

原理图如图, 参考自VESC6的开源原理图

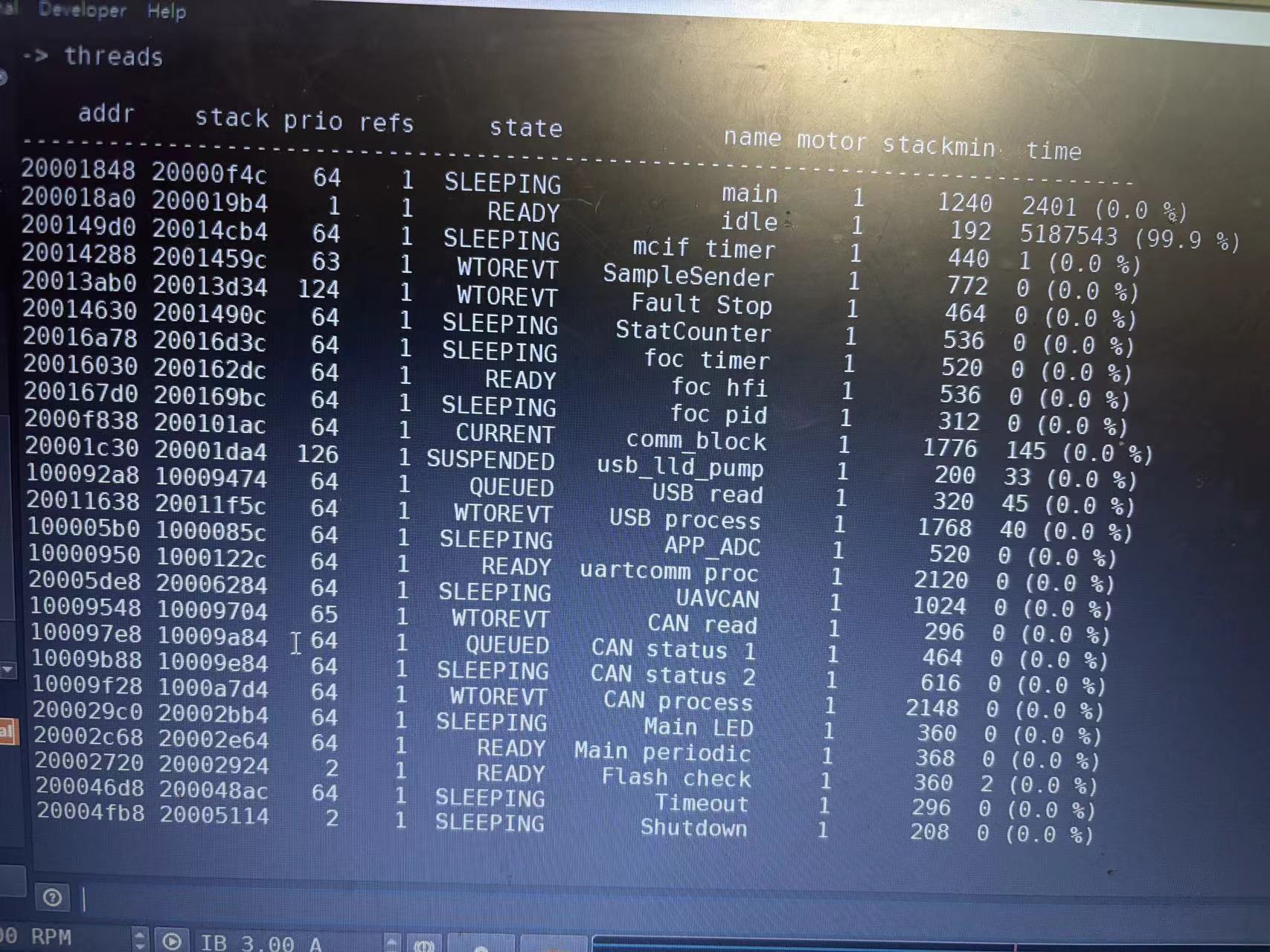

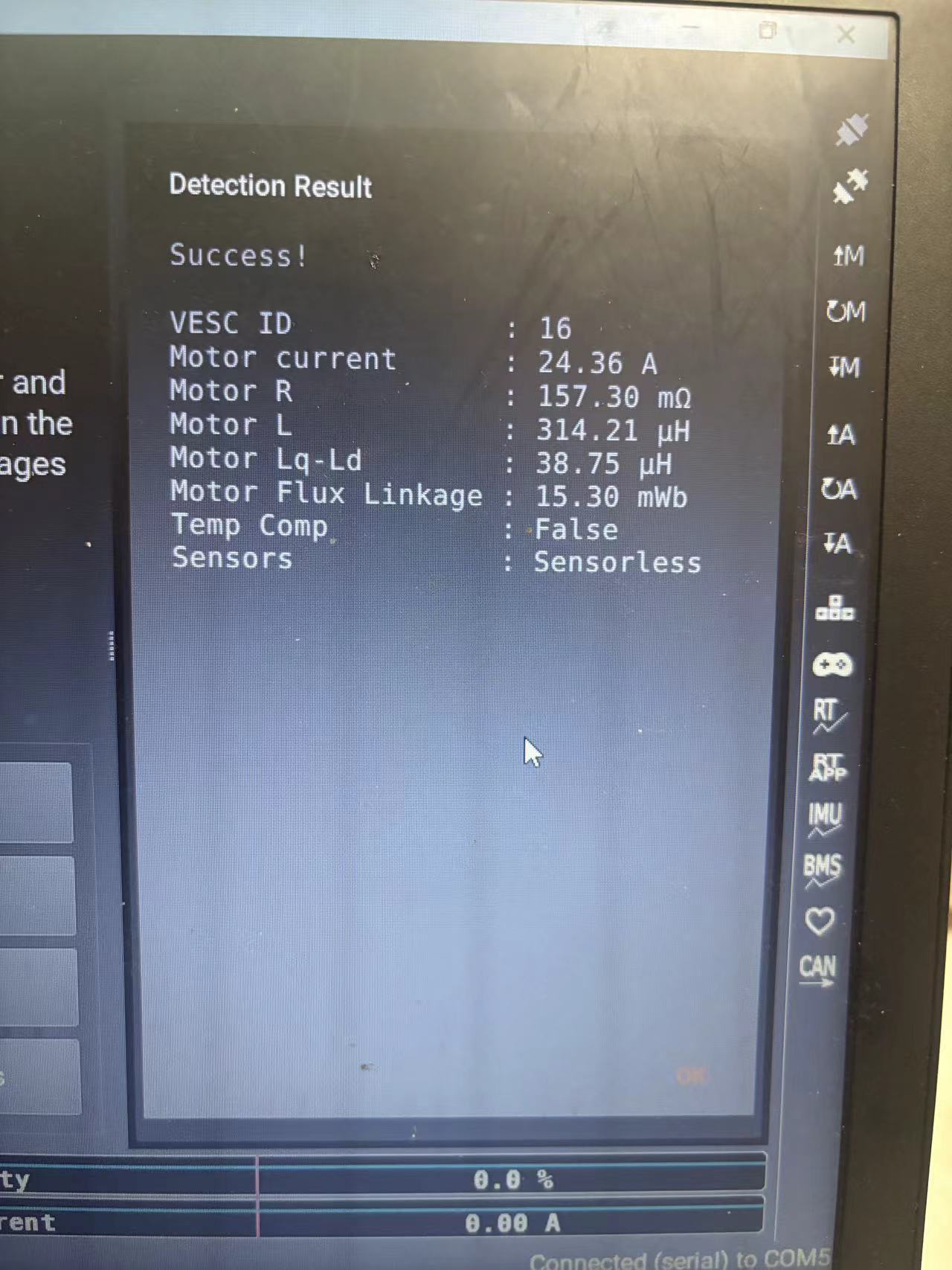

四层板, PCBA也打样回来了,通过开源的上位机VESC tool确认板子的功能正常.

软件:

在硬件确认完毕之前,曾通过基于L298P的直流电机扩展板调试视觉处理软件.

基于视觉的巡线小车控制程序设计:

图像处理:

拍摄图像并二值化

进行开运算和高斯滤波去噪

通过线性回归检测巡线

PID控制:

计算位置误差

rho_err和角度误差theta_err使用两个PID控制器分别处理位置和角度误差

电机控制:

根据PID输出调整左右轮速度实现差速转向

无线条时原地旋转寻找线路

代码在OPENMV 基于micro python快速原型的. 并由Deep Seek优化后测试的

from math import pi, isnan

from machine import Pin

import utime

import sensor, image, time

INVERSE_LEFT = False # 左轮反转 INVERSE_RIGHT = False # 右轮反转

THRESHOLD = (0, 20, -10, 10, -10, 10) MIN_MAGNITUDE = 8 # 最小检测可信度 SEARCH_SPEED = 30 # 搜索速度 BASE_SPEED = 50 # 基础速度 MAX_OUTPUT = 40 # 最大输出限制

RHO_PID_PARAMS = {'p': 0.5, 'i': 0.01, 'd': 0.1} THETA_PID_PARAMS = {'p': 0.8, 'i': 0.02, 'd': 0.15}

========== 硬件初始化 ==========

class HardwareController:

def __init__(self):

self._init_pins()

self._init_pwm()

self._init_sensor()

def _init_pins(self):

"""初始化所有GPIO引脚"""

self.ledb = Pin(("BLUE", 0x0102))

self.ain1 = Pin(('A1', 0x002))

self.ain2 = Pin(('A2', 0x004))

self.bin1 = Pin(('B1', 0x005))

self.bin2 = Pin(('B2', 0x009))

self.tim1 = Pin(('T1', 0x006))

self.tim2 = Pin(('T2', 0x003))

def _init_pwm(self):

"""初始化PWM控制器"""

self.pwm_controller = MultiSoftwarePWM(frequency=1000)

self.ch1_id = self.pwm_controller.add_channel(self.tim1)

self.ch2_id = self.pwm_controller.add_channel(self.tim2)

def _init_sensor(self):

"""初始化摄像头传感器"""

sensor.reset()

sensor.set_vflip(True)

sensor.set_hmirror(True)

sensor.set_pixformat(sensor.RGB565)

sensor.set_framesize(sensor.QQQVGA) # 80x60

sensor.skip_frames(time=2000)

print("Sensor initialized")========== 软件PWM实现 ==========

class MultiSoftwarePWM:

def __init__(self, frequency=1000):

self.frequency = frequency

self.period_us = 1000000 // frequency

self.channels = []

self.last_time = utime.ticks_us()

def add_channel(self, pin):

channel = {

'pin': pin,

'duty_cycle': 0,

'high_time': 0

}

self.channels.append(channel)

return len(self.channels) - 1

def pulse_width_percent(self, channel_id, percent):

"""设置PWM占空比"""

if 0 <= channel_id < len(self.channels):

percent = max(0, min(100, percent)) # 限制范围

self.channels[channel_id]['duty_cycle'] = percent

self.channels[channel_id]['high_time'] = (self.period_us * percent) // 100

def update(self):

"""更新PWM输出(需要在主循环中频繁调用)"""

current_time = utime.ticks_us()

elapsed = utime.ticks_diff(current_time, self.last_time)

if elapsed >= self.period_us:

self.last_time = current_time

# 周期开始,所有引脚置高

for channel in self.channels:

channel['pin'].value(1)

else:

# 检查每个通道是否应该置低

for channel in self.channels:

if elapsed >= channel['high_time']:

channel['pin'].value(0)========== PID控制器 ==========

class PID:

def __init__(self, p=0, i=0, d=0, imax=0):

self._kp = float(p)

self._ki = float(i)

self._kd = float(d)

self._imax = abs(imax)

self._integrator = 0

self._last_error = 0

self._last_derivative = float('nan')

self._last_t = 0

self._RC = 1 / (2 * pi * 20) # 低通滤波器

def get_pid(self, error, scaler=1):

"""计算PID输出"""

tnow = utime.ticks_ms()

dt = tnow - self._last_t

# 时间处理

if self._last_t == 0 or dt > 1000:

dt = 0

self.reset_I()

self._last_t = tnow

delta_time = float(dt) / 1000.0

# 比例项

output = error * self._kp

# 微分项(带低通滤波)

if abs(self._kd) > 0 and dt > 0:

if isnan(self._last_derivative):

derivative = 0

self._last_derivative = 0

else:

derivative = (error - self._last_error) / delta_time

# 低通滤波

derivative = self._last_derivative + \

((delta_time / (self._RC + delta_time)) * \

(derivative - self._last_derivative))

self._last_error = error

self._last_derivative = derivative

output += self._kd * derivative

output *= scaler

# 积分项

if abs(self._ki) > 0 and dt > 0:

self._integrator += (error * self._ki) * scaler * delta_time

# 积分限幅

self._integrator = max(-self._imax, min(self._imax, self._integrator))

output += self._integrator

return output

def reset_I(self):

"""重置积分项"""

self._integrator = 0

self._last_derivative = float('nan')========== 巡线控制器 ==========

class LineFollower:

def __init__(self):

self.hw = HardwareController()

self.rho_pid = PID(**RHO_PID_PARAMS)

self.theta_pid = PID(**THETA_PID_PARAMS)

self.clock = time.clock()

self.state = "SEARCHING"

self.lost_counter = 0

self.max_lost_frames = 30

def process_image(self, img):

"""图像处理流水线"""

img.binary([THRESHOLD])

img.open(1) # 开运算去噪

img.gaussian(1) # 高斯滤波

return img.get_regression([(100, 100)], robust=True)

def calculate_errors(self, line, img_width):

"""计算位置和角度误差"""

rho_err = abs(line.rho()) - img_width / 2

if line.theta() > 90:

theta_err = line.theta() - 180

else:

theta_err = line.theta()

return rho_err, theta_err

def run_motors(self, left_speed, right_speed):

"""控制电机运行"""

# 方向处理

if INVERSE_LEFT:

left_speed = -left_speed

if INVERSE_RIGHT:

right_speed = -right_speed

# 设置方向

self.hw.ain1.value(left_speed >= 0)

self.hw.ain2.value(left_speed < 0)

self.hw.bin1.value(right_speed >= 0)

self.hw.bin2.value(right_speed < 0)

# 设置PWM

self.hw.pwm_controller.pulse_width_percent(

self.hw.ch1_id, abs(left_speed))

self.hw.pwm_controller.pulse_width_percent(

self.hw.ch2_id, abs(right_speed))

def handle_line_detected(self, line, img):

"""处理检测到线条的情况"""

rho_err, theta_err = self.calculate_errors(line, img.width())

# 绘制检测线

img.draw_line(line.line(), color=127)

if line.magnitude() > MIN_MAGNITUDE:

# PID控制

rho_output = self.rho_pid.get_pid(rho_err, 1)

theta_output = self.theta_pid.get_pid(theta_err, 1)

output = rho_output + theta_output

# 输出限制

output = max(-MAX_OUTPUT, min(MAX_OUTPUT, output))

self.run_motors(BASE_SPEED + output, BASE_SPEED - output)

self.state = "FOLLOWING"

# 修复的print语句 - 使用传统格式化

print("FOLLOWING: Rho_err=%.1f, Theta_err=%.1f, Output=%.1f, Mag=%d" %

(rho_err, theta_err, output, line.magnitude()))

else:

print("Low confidence, stopping")

self.run_motors(0, 0)

self.state = "UNCERTAIN"

def handle_no_line(self):

"""处理未检测到线条的情况"""

self.lost_counter += 1

if self.lost_counter > self.max_lost_frames:

self.state = "LOST"

print("Line completely lost! Aggressive search")

self.run_motors(SEARCH_SPEED, -SEARCH_SPEED) # 原地旋转

else:

self.state = "SEARCHING"

self.run_motors(SEARCH_SPEED // 2, -SEARCH_SPEED // 2) # 温和搜索

# 修复的print语句

fps = self.clock.fps()

print("%s: FPS=%.1f, Lost frames=%d" %

(self.state, fps, self.lost_counter))

def main_loop(self):

"""主控制循环"""

print("Starting line follower...")

self.hw.ledb.value(1) # 开启状态指示

try:

while True:

# 更新PWM

self.hw.pwm_controller.update()

# LED状态指示

self.hw.ledb.value(not self.hw.ledb.value())

# 图像处理

self.clock.tick()

img = sensor.snapshot()

line = self.process_image(img)

# 状态处理

if line:

self.lost_counter = 0

self.handle_line_detected(line, img)

else:

self.handle_no_line()

# 短暂延时,保持PWM更新频率

utime.sleep_ms(5)

except KeyboardInterrupt:

print("Program interrupted by user")

except Exception as e:

print("Unexpected error: " + str(e))

finally:

self.cleanup()

def cleanup(self):

"""清理资源"""

print("Cleaning up...")

self.run_motors(0, 0) # 停止电机

self.hw.ledb.value(0) # 关闭LED

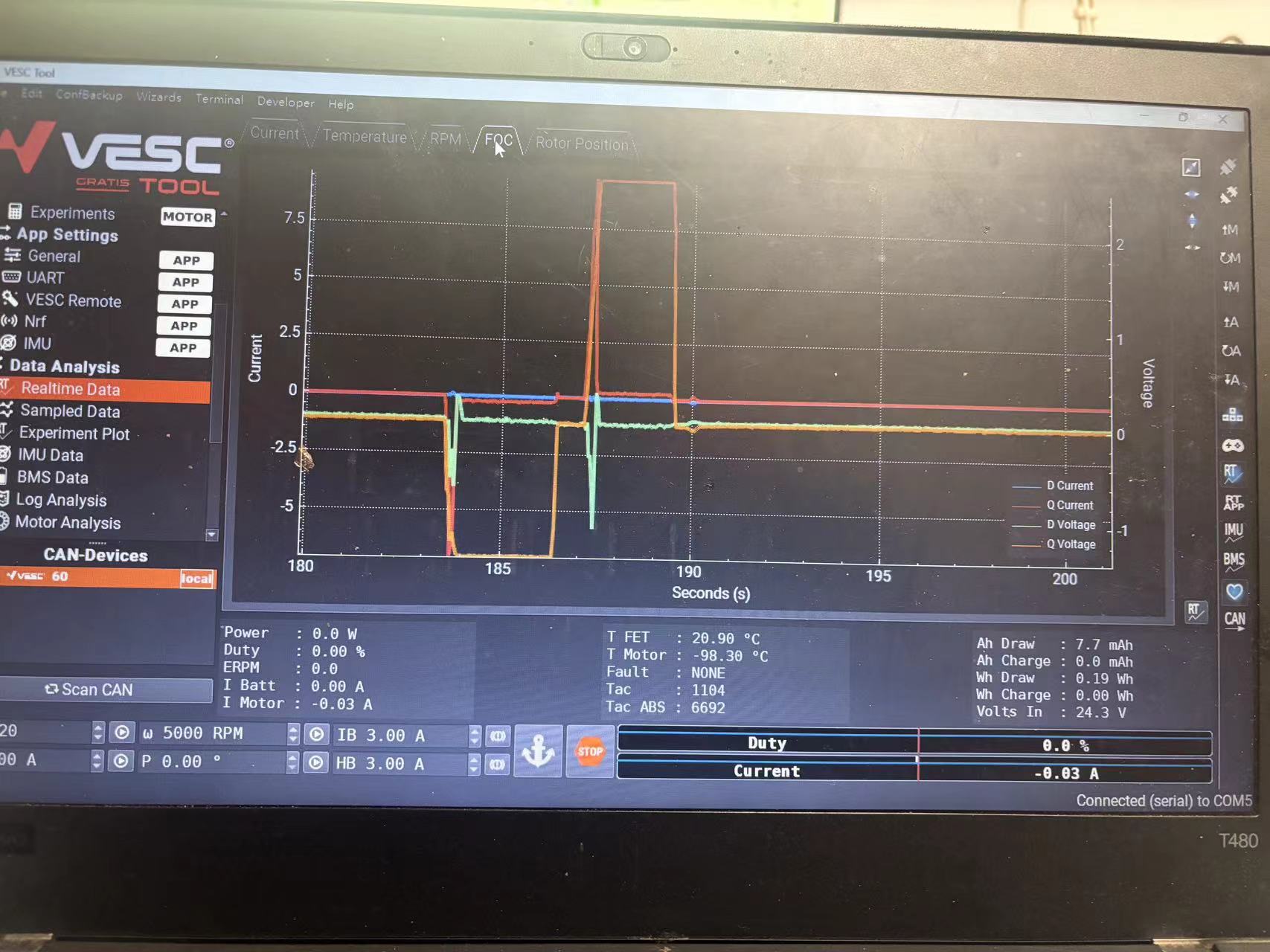

print("Cleanup completed.")在硬件确认后,结合视觉处理软件,调试VISION BOARD 和VESC通过UART/CAN的协同工作,UART数据发出后VESC响应还有些问题,后续更新中。

========== VESC通信协议 ==========

def vesc_set_rpm(rpm: int):

"""设置转速"""

payload = struct.pack('>i', rpm)

cmd = 0x08 msg = bytes([cmd]) + payload msg_len = len(msg)

data = bytes([msg_len >> 8, msg_len & 0xFF]) + msg

checksum = crc16(data)

packet = b'\x02' + data + struct.pack('>H', checksum) + b'\x03'

uart.write(packet)

def vesc_stop():

"""停止电机"""

vesc_set_duty(0.0)

ledb.value(0)

========== 电机测试 ==========

def motor_test():

"""简单电机测试"""

print("电机测试开始")

# 正转测试

print("正转1000 RPM - 10秒")

ledb.value(1)

vesc_set_rpm(1000)

for i in range(5, 0, -1):

time.sleep(1)

# 停止

vesc_stop()

time.sleep(1)

# 反转测试

print("反转1000 RPM - 10秒")

ledb.value(1)

vesc_set_rpm(-1000)

for i in range(5, 0, -1):

time.sleep(1)

# 最终停止

vesc_stop()

print("电机测试完成")总结:

基于Vision Board的电驱扩展板 凭借其合适的模块化设计,主要负责电机驱动的任务, Vision Board 集成的OPENMV 和MicorPython 可以快速调试摄像头采集图片并处理图片,分析路线角度并调整电机前进方式,是前进 左右转还是停止. Vision Board 是做巡线小车的得力助手, 可以高效的完成图像处理和小车前进方向的识别.

感谢:

衷心感谢RT-Thread与华秋携手组织本次富有意义的活动,为我们广大开发者提供了宝贵的交流与实践平台。

同时,我们也期待RT-Thread未来能推出更多让开发者深度参与活动,在现有线上形式基础上,逐步拓展至线下交流,通过与开发者多元互动,增添行业活力..

再次感谢RT-Thread、华秋及所有相关组织者的辛勤付出与支持!